Due to the desirable Torque-speed characteristics, the series motor is exclusively used in traction applications. Dc series motor satisfy all requirements for this kind of work and services but the transmission of ac power is more economical than DC. This has led to the development of the Ac series motor.

This motor is a kind of motor in which construction is done to work on both DC and Ac single-phase supply. The working principle is the same as the dc series motor and has advantages of the dc series motor like high torque.

Table of Contents

The DC motor which runs on alternating supply called an Ac series motor. However, some changes must be made in the DC series motor that is to operate satisfactorily on alternating supply.

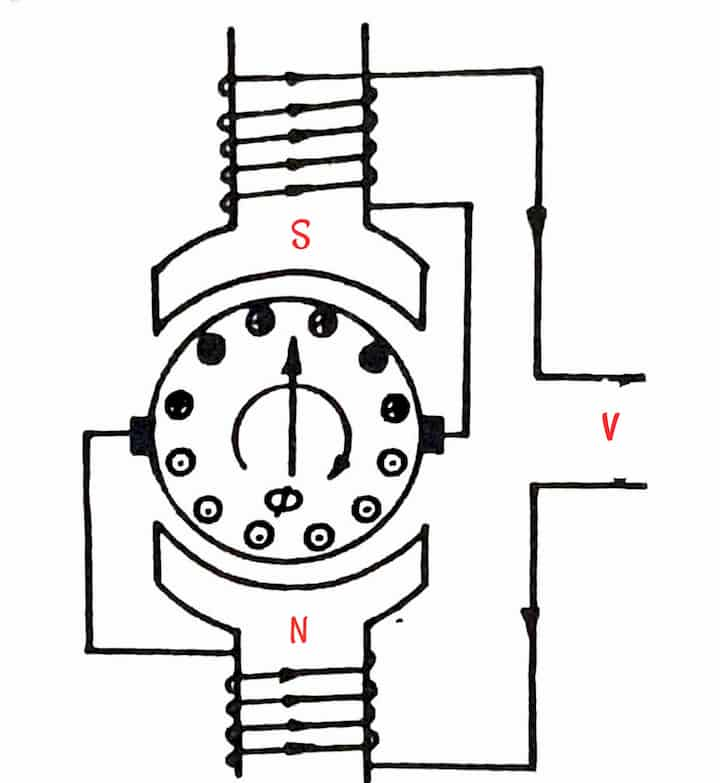

Construction of AC series Motor

The construction of the ac series motor is identical to the dc series motor except for some changes as given follows:

- The magnetic circuit must be laminated.

- The field circuit must be designed for much lower reactance than the dc motor field in order to reduce the reactance voltage drop of the field and improve the power factor.

- Distributed compensation winding is required to minimize the reactance of armature winding.

- The compensating winding may be connected in series with the field and armature winding called conductively compensated and conductively compensation required armature which is designed to operate on AC and dc voltage.

- If compensation winding short-circuited to itself and received excitation voltage by transformer action called inductively coupled.

Working Principle of AC Series Motor

The working principle is the same as the DC series motor. When the AC series motor is connected to the AC supply the alternating current starts flowing through the field and armature winding.

The field winding produces an alternating flux Φ that reacts with the current flowing in the armature winding to produce a torque. Since both armature and field current reverse simultaneously. the torque is always produced in the same direction.

Due to its high starting torque and high-speed, it finds more applications.

Motor particularly designed to run on DC power suffers following drawbacks when it started on a single-phase ac supply.

- Its efficiency is low due to hysteresis and eddy current losses.

- Its Power factor is low due to the large reactance of field and armature winding.

- Sparking at the brushes is more.

To run efficiently on ac supply following constructional modifications are done.

- Field core is constructed using a material that has low hysteresis losses and it laminated to reduced eddy current.

- The field winding is constructed with small numbers of turns due to this pole area increase and flux density decrease this reduced iron losses and reactive voltage drop.

- The number of armature conductors increases to achieve the required torque with low flux. Compensation winding is used to reduce armature reaction and increase commutation.

Characteristics

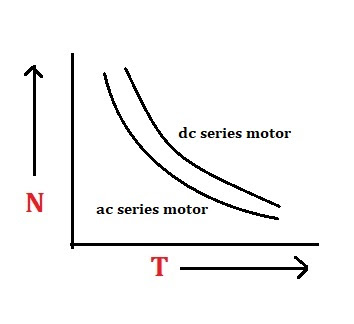

The torque-speed characteristic of an ac series motor is shown in the below diagram

we can see from torque-speed characteristics that the series motor develops high starting torque at low speed.

it is because the increase in torque increases field and armature current the result in that flux strengthened and hence speed drops. torque is directly proportional to the square root of the current 𝜏∝I2

Application of AC Series Motor

- High-speed vacuum cleaner

- Sewing machines

- Used in drills and power tools

- Electric shavers