Why Earthing/grounding testing is Necessary?

Testing the quality of the Earthing system has been a critical part of any electrical system maintenance program.

Ground electrodes provide a safe path to Earth for the dissipation of fault currents, lightning strikes, static charges, and EMF/RFI signals.

Over time, ground systems deteriorate due to environmental conditions or catastrophic events (like lightning strikes). Alternatively, facility expansion may change needs in the installed ground system.

The risks from ground system deterioration include potentially deadly electrical shocks, plant-wide equipment damage, disruption in the performance of sensitive electrical equipment, heat build-up and eventually fire on a single piece of electrical equipment, and disruption in digital communication service.

Earth Pit testing methods

Fall of Potential Method

Testing Procedure

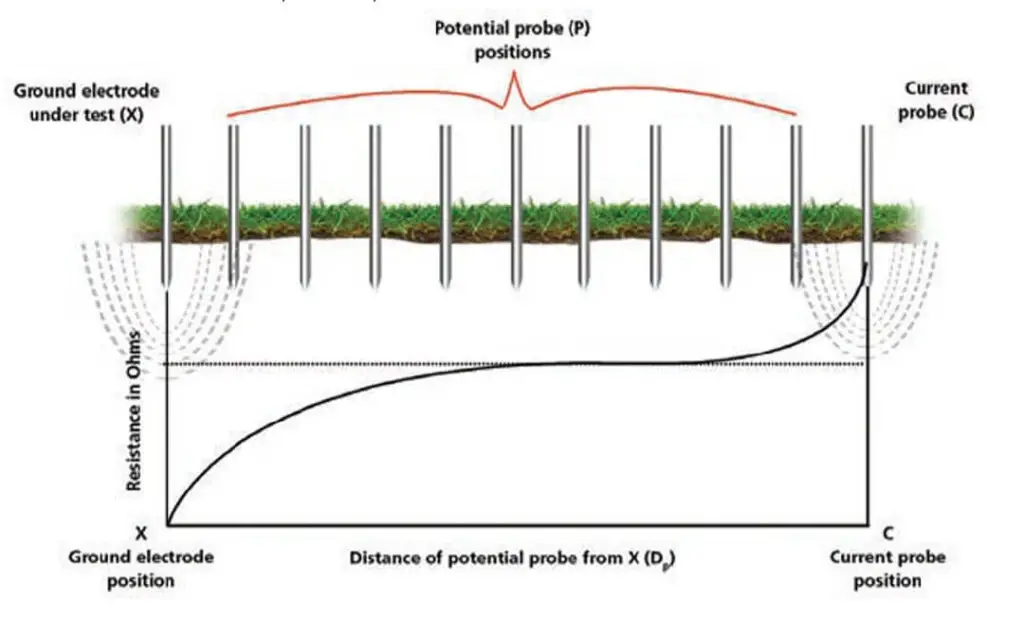

Proper fall of potential testing involves placing a current probe in the soil at a distance from the ground electrode being tested (before testing please verify that the ground electrode must be disconnected from the system).

The actual distance is determined by the ground electrode/system size.

The earthing tester is then connected to the ground electrode under test, the current probe and a potential probe.

The potential probe is placed in the soil at distances of 10%, 20%, 30%, up to 90% of the distance between the ground electrode and the current probe and a reading is taken at each location.

The readings are then plotted against the distances and the point where the curve flattens is the approximate resistance of the ground electrodes.

The fall of potential method is extremely reliable, as the results can be checked by testing at different current probe distances.

This method has three important disadvantages:

- It is exceedingly time-consuming and labor-intensive.

- The operator must disconnect the ground electrode to make the test. As a result, the system is not protected during the test.

- In real-world situations, space constraints can make it difficult to place the remote probes.

Clamp-On Testing earth Pit tester

The clamp-on ground tester is an effective and time-saving method when used correctly because the user does not have to disconnect the ground system to make a measurement or place probes in the ground.

The method is based on Ohm’s Law,

where,

R (resistance) = V (voltage) / I (current).

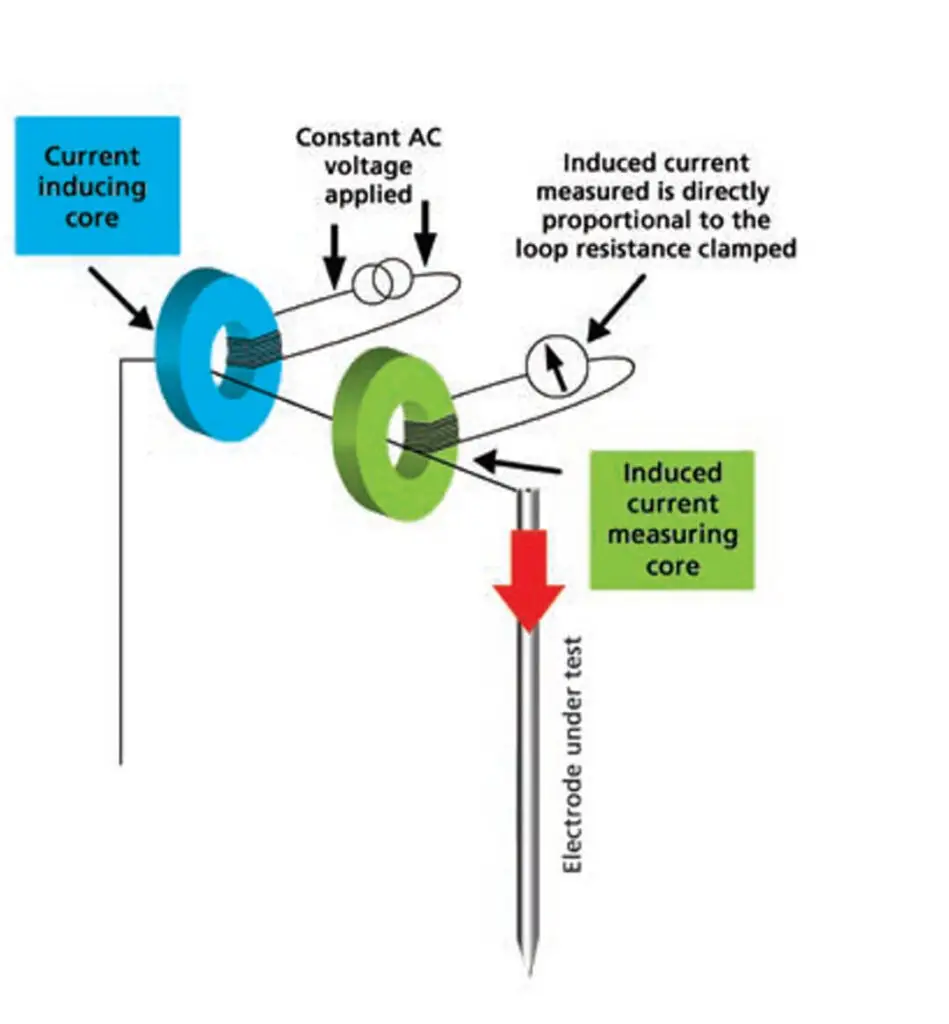

The clamp includes a transmit coil, which applies the voltage and a receive coil, which measures the current.

The instrument applies a known voltage to a complete circuit, measures the resulting current flow and calculates the resistance.

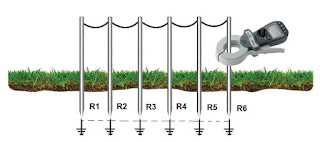

The clamp-on method requires a complete electrical circuit to measure.The operator has no probes and therefore cannot set up the desired test circuit. The operator must be certain that earth is included in the return loop. The clamp-on tester measures the complete resistance of the path (loop) that the signal is taking. All elements of the loop are measured in series.

The method assumes that only the resistance of the ground electrode under test contributes significantly. Based on the math behind the method (to be reviewed later), the more returns, the smaller the contribution of extraneous elements to the reading and, therefore, the greater the accuracy. The major advantage of the clamp-on method is that it is quick and easy. The ground electrode does not have to be disconnected from the system to take the measurement and no probes need to be driven and no cables connected.

how does clamp-on method earthing testing work?

The clamp-on test method is based on Ohm’s Law (R = V/I).

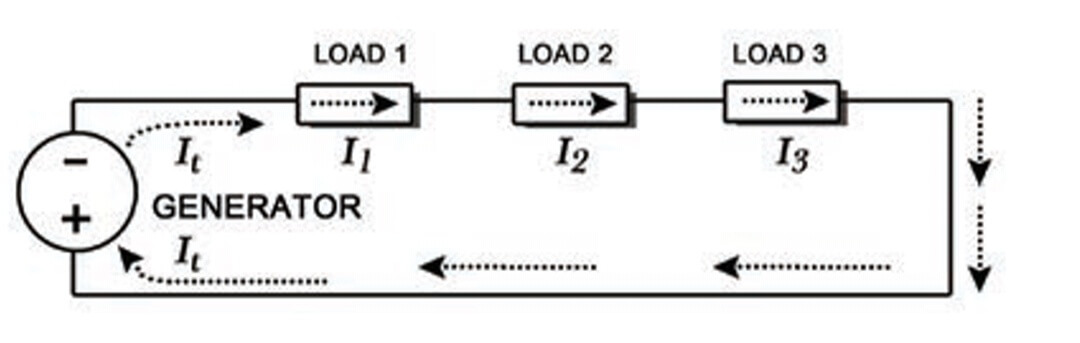

Understanding Ohm’s law and how it applies to series and parallel circuits is the first step to understanding how and why a clamp-on ground tester works.

The following graphics will show a series circuit, a parallel circuit and a parallel-series circuit, and the math used to determine the total current and resistance.

I=I₁=I₂=I₃

Rt = R1 + R2 + R3

I=I₁+I₂+I₃

Rt = 1/ (1/R1 + 1/R2 + 1/R3)

Clamp-On Test Methodology

The head of a clamp-on ground tester includes two cores (see figure). One core induces a test current and the other measures how much was induced. The input or primary voltage of the test current inducing core is kept constant, so the current actually induced into the test circuit is directly proportional to the loop resistance. The important thing to remember with clamp-on testing is that clamp-on ground testers effectively make loop resistance measurements.

Clamp-on measurements are loop measurements. For the clamp-on method to work there must be a series parallel resistance path (and the lower the better). The more electrodes or ground paths in the system the nearer the measurement gets to the actual electrode under test’s true resistance. The following figure shows a pole ground configuration, one of the most effective applications of the clamp on ground tester.

Reference//

Guide to Clamp-on Ground Testing megger