Electricity, such an integral part of our daily life, is not possible without the complex network of cables. One type of cable extensively utilized in protective electrical installations is the armoured cable – a uniquely constructed that ensures constant and safe electrical conduction. This information pack aims to unravel the complexity of armoured cable, elucidating its construction, types, applications, installation techniques, and safety measures.

Ideally, after navigating through this myriad of information, you’ll see why armoured cable is far more than just a conduit carrying power – it’s a shielded safeguard designed precisely for the dangerous yet indispensable force that is electricity.

Armoured Cable

Armoured cable is a type of power cable specifically designed to provide additional mechanical protection in both outdoor and indoor environments. Its hallmark characteristic is its additional ‘armour’ – a protective outer layer typically made of materials like steel.

This metallic armour is installed over the insulating layers of the cable to protect the conductors from damage, thus ensuring durability, reliability, and safety.

Construction of Armoured Cable

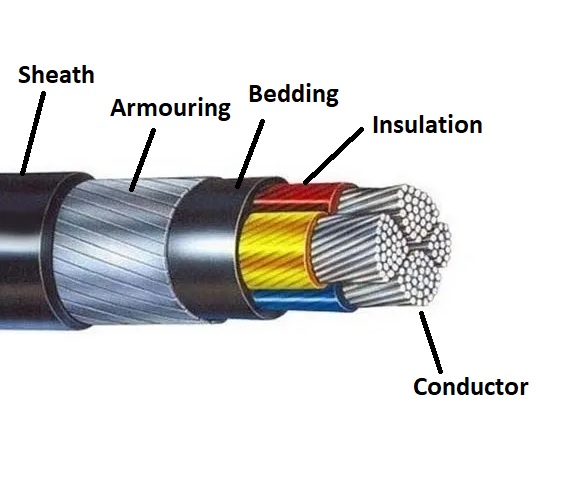

The layers comprising the armoured cable are numerous, each serving a particular role.

Conductor

These are the core components of the cable responsible for carrying electrical current. Copper and aluminium are commonly used materials due to their high electrical conductivity.

Insulation

The insulation layer surrounds the conductors to prevent current leakage and protect users from electric shocks. Materials like PVC, XLPE, and EPR are commonly used for insulation.

Bedding

A bedding layer is then placed around the insulator which is subsequently covered by the metallic armour to provide mechanical protection. This combination assures the carrying of electrical power safely and efficiently while enduring various conditions. Armoured cables are extensively used in electrical installations, especially where damage risk is high. These cables are prevalent where the cables have to withstand harsh and hazardous environments.

Armour

The armour is the mechanical protection layer that shields the cable from external stresses such as physical damage, rodent attacks, and extreme conditions. Different types of armour, like steel wire, steel tape, or aluminium, can be used based on the application.

Sheath

The sheath or jacket is the outermost layer of the armoured cable, serving as a protective cover against environmental factors like moisture, chemicals, and UV radiation. The choice of sheath material (PVC, LSZH, neoprene, etc.) depends on the cable’s specific use and location.

Specifications of Armored Cable

Armored cable offers a wide array of benefits such as enhanced safety, lasting durability, and strength, bolstered by its distinct construction.

The sturdy nature of this cable enables it to withstand tremendous stress, while its flexibility allows it to be installed in a myriad of locations, including tight corners and restricted spaces.

It offers remarkable resistance to moisture, heat, fire, and chemical decay, and can tolerate physical damage from either underground or above-ground installations, making it a popular selection across numerous industries.

In addition, the metallic armor serves as a conduit for electrical current, adding a safeguard against electrical shocks and circuit failures.

These attributes position armored cables as a critical element in various applications.

Types of Armoured Cable

There are several types of armored cables, each tailored for specific purposes. Noteworthy types include steel wire armored (SWA) cables, steel tape armored (STA) cables, and aluminum wire armored (AWA) cables.

Steel Wire Armored (SWA) Cables

SWA cables are robust and commonly employed in direct burial, ducts, as well as external and internal cabling applications due to their superior resistance to mechanical strains and certain corrosive environments.

Steel Tape Armored (STA)

STA cables are largely used in installations that require a high degree of mechanical protection as they are adept at resisting crushing forces.

Aluminum Wire Armored (AWA) Cables

AWA cables are lightweight and regularly utilized in corrosive environments thanks to their anti-corrosive traits.

Uses of Armoured Cables

Armoured cables find their place in a broad array of applications, spanning across industrial, commercial, and domestic arenas. In an industrial context, these cables are often integral to power distribution processes in factories, plants, and refineries.

For instance, an oil and gas refinery may implement armoured cables to maintain a steady power supply and communication lines under demanding operational circumstances where durability and resistance to harsh environments are essential.

An example of this is the frequent use of Steel Wire Armoured (SWA) cables in high-rising residential or commercial structures, given their ability to resist heavy loads and prevent potential electrical incidents.

Installation and Safety Measures for Armoured Cable

Armoured Cable Installation

The process of installing an armoured cable is markedly more meticulous than typical cable installations due to the cable’s unique structure.

The first step is to measure the required cable length for the specific use case. Once this is done, a precise cut is made to the cable using a specialized handsaw or an armoured cable cutter.

After cutting, the armoured covering is stripped off to display the internal conductor wires. Subsequently, the cable is threaded along the designated path and placed within the electrical box.

This procedure demands utmost care to ensure that the armoured layer is stripped correctly without inflicting any damage to the internal wiring, which can compromise efficacy and safety.

Safety Measures and Code Compliance during Installation

Working with electricity and electrical components always has inherent risks, so it’s essential to adhere to a strict set of safety measures.

Before beginning the installation process, make sure to turn off the power supply to avoid any unintentional electrical shocks.

When stripping the sheathing of the armored cable, care must be taken to avoid nicking or damaging the conductor wires. Damaged wires can cause electrical shorts, leading to potential fire hazards.

As for code compliance, any armored cable installation must comply with the National Electric Code (NEC). The NEC prescribes various standards to ensure the secure and safe installation of armored cables, including adequate support and securing for the cables and proper stuffing of boxes.

It is recommended to have a professional electrician or a knowledgeable person to supervise or perform the installation, as they would be familiar with the nuances and safety requirements of working with armored cables.

As you navigate through the world of electrical installations, armoured cables may stand as an unassumingly crucial player.

They prove to be a diligent protector against physical damages and electrical interference, making them remarkable for a wide range of applications – industrial, commercial, or residential.

By understanding and following the necessary installation and safety procedures, we maintain an effective electrical network, keeping the energy flowing reliably and securely.

So, while the armoured cable might be out-of-sight in our walls, underground, or within our industrial machineries, their role is far from insignificant.

Indeed, in the realm of electrical infrastructure, the contribution of armoured cables is such that they cannot be overlooked nor underappreciated.