Induction motor is mostly used motor in the industry as well as in domestic application because it’s a simple design, reliable operation, rugged construction, and simple control gear for starting, speed control, and three phase induction motor braking like plugging, dynamic and regenerative braking.

The most simple method to stop the motor is to disconnect the motor terminal from the supply and apply braking to the motor.

When rapid and more positive stopping action is required mechanical or electrical braking may be employed. induction motor electrical braking methods like plugging( counter-current braking), dynamic braking or rheostatic braking, and regenerative braking.

Table of Contents

3-Phase Induction Motor Braking

Following are the three main types of electrical braking of three-phase induction motor

- Plugging/ Reverse voltage braking

- Regenerative induction motor braking

- Dynamic induction motor braking

Plugging Braking of Induction Motor

Plugging braking of the three-phase induction motor is carried out by changing the phase sequence of the induction motor. this method is also called reverse voltage braking. Plugging braking is done by interchanging connections of any two leads of the motor with respect to supply terminals.

A three-phase induction motor develops torque in the same direction as the rotating magnetic field (RMF) generated by the stator winding of the induction motor also in any two stator winding leads that are reversed the rotating magnetic field also gets reversed. hence if stator leads reverse by any means while motor rotating, torque is suddenly produced opposite to the original direction of rotation.

These reverse torque cause rotation in the opposite direction as soon as the motor stops, therefore, the arrangement must be made to disconnect the stator completely from supply lines when the motor stops. A plugging controller must be used along with the switch.

The plugging switch is connected to the motor and opens when the motor stops. It is connected to the control circuit so that it allows the operation of controllers reversing current when the motor rotates in a given direction only when the motor stops, the reversing circuit gets opened by plugging the switch, and the motor gets completely disconnected from the supply.

When the stator field reverses the slip suddenly increases from a small percentage to 200 %. Since the rotor and stator field are now rotating in opposite directions. The rotor-induced voltage also increases by a large amount. Hence there is a large inrush of stator current. The high slip causes high rotor reactance and hence a very low power factor in the stator of the induction motor.

After plugging braking of the induction motor has started when the motor stops slip is unity and the current and power factor are the same as when the motor started with full supply voltage. The above condition occurs during a very long period of time they may cause disturbances in supply.

Regenerative Braking of Induction Motor

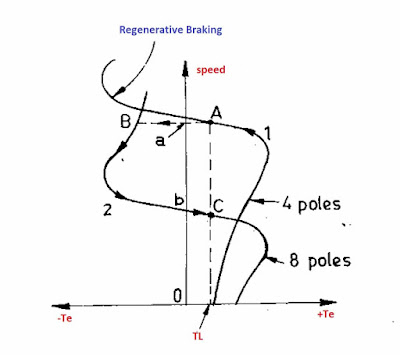

Regenerating braking of the induction motor takes place when the motor runs above the synchronous speed, when the rotor speed, becomes more than the rotating field speed, the slip becomes negative. The negative slip means that the induction motor now operates as an induction generator in the second quadrant and feeds back power to the supply line.

The power fed to supply is given by the product of regenerative braking torque and the corresponding rotor speed. Fig shows that the amount of power returned to the supply line depends upon how much rotor speed is above synchronous speed. When rotor speed falls to synchronous speed, the regenerating braking of an induction motor comes to an end.

Dynamic Braking of Induction Motor

Dynamic braking of the three-phase induction motor is the slowing down of the motor by converting the kinetic energy stored in the rotating mass to the heat energy in the rotor/stator windings.

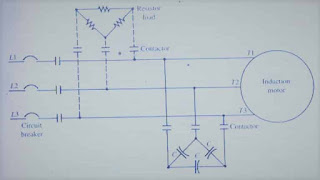

To achieve dynamic braking, the motor is switched from the supply line to a braking circuit that causes the motor act as a generator with a connected load.

The load is the resistance of the rotor or stator windings. since the only sources of energy are the rotating parts of the induction motor and the motor-driven equipment.

Dynamic braking of the 3-phase induction motor can be accomplished by DC voltage injection or capacitive braking.

Disadvantage of this type of braking is it does not provide holding torque at the end of the braking period. Hence, where it required a mechanical brake must be used to hold the shaft. e.g hoist application where rolling is not permitted after a stop.