The type of motor that operates on both DC and single phase AC supply is called Universal Motor. The universal motor is also called an ac series motor. The universal motor works at approximately the same speed and output on either DC or AC single-phase supply.

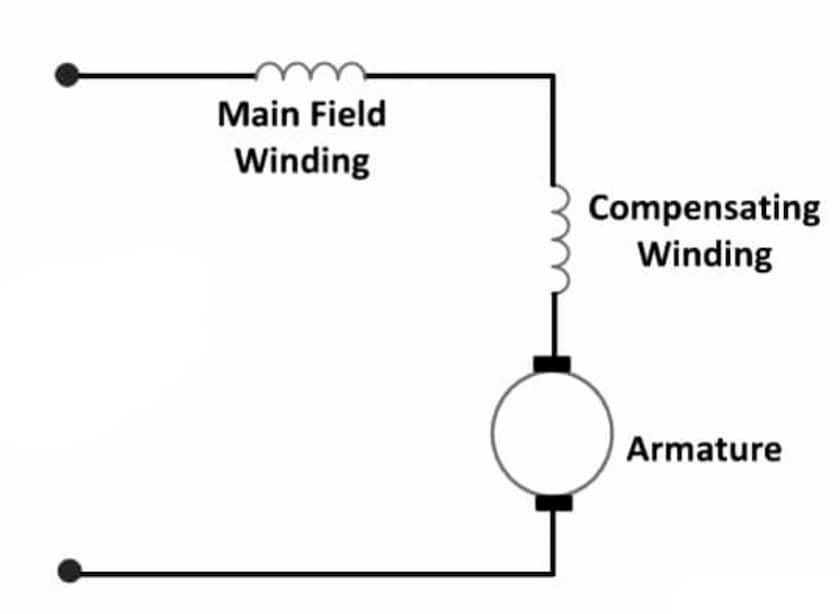

The universal motor is a series-wound motor which means field winding and armature windings are connected in series. It has high starting torque and variable speed characteristics. It runs at dangerously high speed when running at no load.

Universal motors are designed for commercial frequencies from 50Hz or 60Hz to DC zero frequency and for voltage rating 250V to 1.5V.

Table of Contents

Universal motors are generally used in Electric hand drills, vacuum cleaners, electric shaver, sewing machines, and in many more applications.

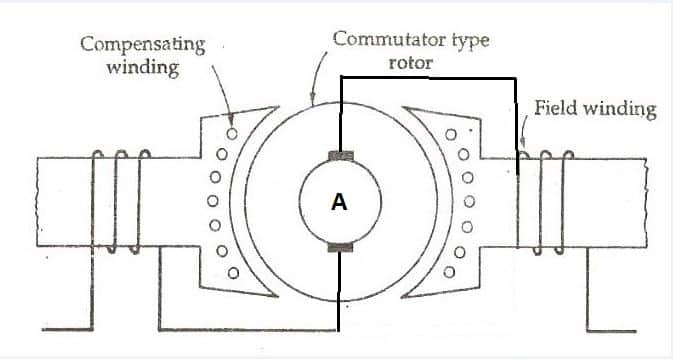

This motor is a commutator type motor.

If an ac series motor is connected to an AC supply it will rotate and exert one-directional torque because the current flowing in both field and armature is the same and reverse at the same time.

The direction of torque developed in DC series motor is determined by both field polarity and the direction of current flowing through armature winding.

Construction Of Universal Motor

The construction of a universal motor is identical to the construction of a DC series motor. It is a series-wound motor that means field and armature windings are connected in series. the universal motor diagram is shown below

Types of Universal Motor

Generally constructed in two types

- Non compensated with concentrated pole type

- Compensated with distributed field type

Non compensated with concentrated pole types

The non compensated type universal motor has 2 salient poles like DC series motor except the laminated core. The laminated stator is constructed to reduced eddy current losses because the flux is alternating when it operated on AC supply.

The armature is wound type same as small dc motor, it has laminated core having straight or skewed slots and commutator to which armature winding leads are connected.

Compensated with Distributed field type

It has a stator same as the split-phase motor and wound type armature similar to that small dc motor.

In compensated type motor, compensating winding is used to reduced reactance voltage drop in armature when it operated on AC supply. This voltage is caused by the transformer action due to alternating flux.

If compensated winding connected in series with armature and field winding in such a case motor is called a conductively compensated motor. the connection diagram is shown below.

Working Principle of Universal Motor

Universal motors working principle is the same as the DC series motor works.

Let,

DC series motor connected to single-phase ac supply and the same current flowing through the field and armature windings., hence the ac reversal from positive to negative cycle or from negative cycle to positive will simultaneously affect both field flux polarity and the current direction through armature winding.

This shows that the direction of torque developed will remain positive and rotor rotation will continue in the same direction. Thus, independent of supply fed. universal motors working principle is the same as the DC series motor works.

The nature of torque developed will be pulsating and frequency will be twice the supply frequency. thus universal motor(ac series motor) can run on both DC and single phase AC supply.

AC series motor specially design to run on DC supply suffers following drawbacks when it operated on a single phase AC source.

- Its efficiency is low due to hysteresis and eddy current losses.

- Its Power factor is low due to the large reactance of field and armature winding.

- Sparking at the brushes is more.

To overcome the above drawbacks of dc series motor to run efficiently on ac supply following constructional modifications are done.

Field core is constructed using a material that has low hysteresis losses and it laminated to reduced eddy current.

The field winding is constructed with small numbers of turns due to this pole area increase and flux density decreases this reduced iron losses and reactive voltage drop.

The number of armature conductors increases to achieve the required torque with low flux.

Compensation winding is used to reduce armature reaction and increase commutation.

Advantages of Universal Motor

- Universal motor produced high torque at intermediate speed.

- High speed from above 3600 to 25000rpm.

- High power output in a small size suitable for portable tools.

Disadvantages

- Due to brushes, service requirements are increasing.

- Create radio and television interference due to brush sparking.

- Careful balancing must be required during working to reduce vibrations.

Application of Universal Motor

Applications of the motor are given as follows:

- Universal motors are used in shaving machines, and vacuum cleaners.

- Used in drinking and food mixers, portable drill, sewing machine, in tiles cutter.

This motor is a kind of motor which construction is done to work on both DC and Ac single-phase supply. The working principle is the same as the dc series motor and has an advantage as the dc series motor like high torque.